Teddington is proud to manufacture the KBB fire safety valve – the bestselling remote acting fire safety valve in the UK.

Industry standards necessitate the fitting of remote acting fire safety valves as a fundamental part of any oil boiler installation. They also state that testing should be carried out at least once a year to ensure the valve is operating correctly.

Yet very often this essential component is overlooked – putting properties and lives at risk. Kenneth Maxwell, sales manager at Teddington, explains more.

The KBB is a relatively simple and straightforward component – but failure to fit one, correctly install or carry out regular maintenance can have a potentially devastating impact.

Regional building regulations require all oil-fired boilers to be fitted with a fire safety valve. Insurers will also often look for fire valves as a key safety device on an oil-fired system.

It is therefore essential that technicians performing new boiler installs or replacement works ensure a properly fitted fire valve is in place.

Installation

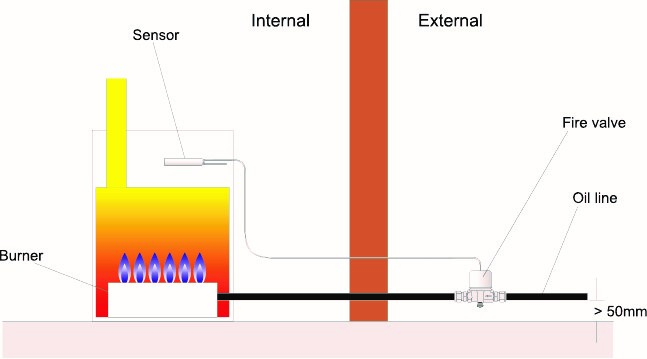

The KBB needs to be fitted in the oil supply pipeline outside the building, a minimum of 50mm from the ground and close to the fuel tank, with the sensor mounted firmly inside the appliance casing above the burner in accordance with the installation instructions. It is important to check correct operation of the KBB before fitting.

Standard KBB fire valve positioning for low level boiler installation

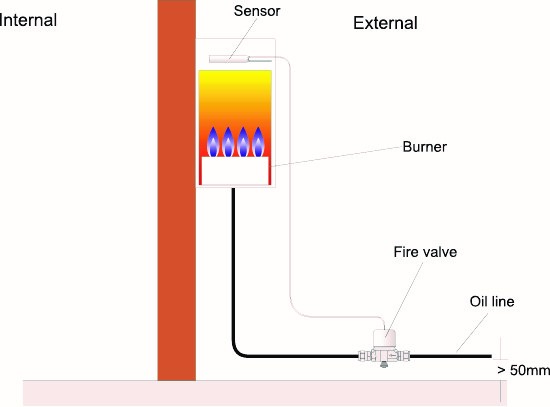

The capillary tube connecting the sensor to the valve should run in a protected position without over-sharp bends, particularly near to the sensor.

When the temperature at the sensor exceeds the set value (either 85OC or 60OC) the valve will snap shut, cutting off the flow of oil to the property.

The KBB will remain in the shut-off position until the appropriate action has been taken to restore normal operating conditions and the reset button has been pressed.

Standard KBB fire valve positioning for external boiler installation

When installing a KBB, it’s important to consider the following:

- The valve should be installed in the oil supply line outside the property

- If installed in any orientation other than horizontal, then it must be protected from the weather

- Do not cut, crimp or compress the capillary tube and avoid tight bends

- Failure due to any water ingress – because of incorrect fitting – will often invalidate any warranty

OFTEC’s OFT-10-600A and OFT10-105E training courses cover the installation of fuel supply systems and the installation of fire safety valves.