KBB Safety Valve

Essential fire protection for oil-fired boilers

- KBB is the Industry Standard

- Non-Electric Safety Valve

- Manual Reset

- Manual On/Off for Appliance Servicing

- Sensor System Fails Safe if Broken

- Two Alternative Temperature Settings

- Remote Sensing Up To 20m (66ft)

- Conforms To BS 5410 Part 1

- Approved To OFS E101

- Bio Fuel Compatible

- Now Available in 3 Thread Sizes: 1/4", 3/8", 1/2"

For more information on the KBB visit the KBB website or email enquire@teddingtonsystems.co.uk “I’ve been associated with the KBB since 1967. It is a very reliable device based on very sound engineering practices. From its inception, it was designed in such a way that it could not have been bettered." Peter Wiltshire, director of trade supplier OH Products

Application

The KBB is a fire safety shut-off valve for use on oil-burning equipment.

The valve is installed in the oil supply pipeline outside the building with the sensor mounted firmly inside the appliance above the burner. The capillary should then be run in a protected position without over-sharp bends particularly near the sensor and valve.

The KBB is the industry standard, and using this valve, property can be safeguarded against the risk of fuel being fed into a fire originating elsewhere than in the heating appliance (most fires in the home are of this type) and also against the risk of fire due to over-temperature of the oil burning equipment.

Physical Description

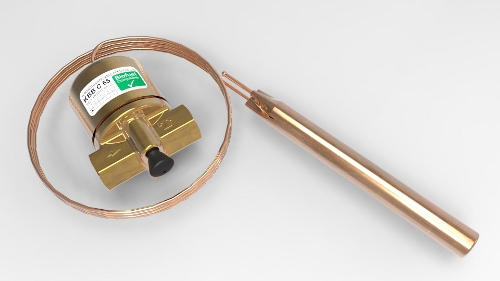

The KBB is a compact valve of corrosion resistant, noncombustible construction and entirely mechanical in operation, requiring no power supply.

The sensor is connected to the valve by a capillary, which cannot be detached. The reset button can be found at the base of the valve head and is pressed to reset the valve or if pulled will toggle the valve into the shut-off condition.

Operation

The KBB is a quick acting thermally operated valve with a spring loaded trip mechanism and sealed temperature sensing system consisting of a bellows, capillary tube and sensor phial.

The valve will snap closed when the temperature at the sensor phial exceeds the set value. The valve will remain in the shut-off condition until the appropriate action has been taken to restore normal operating conditions and the reset button has been pressed.

The operation of the fire valve can be verified by using the KBT1000 test unit set to the appropriate temperature. This checks that the operation to shut-off the oil supply pipe takes place and enables a check to be made that the valve can be manually reset once the sensor phial temperature has reduced to normal operating level. The reset button must be pressed firmly to ensure the valve is positively latched in the open position.

The valve can also be shut-off manually by pulling the reset button.

Additional Information

- The use of remote sensing fire valves is covered by BS 5410: Part 1: 1997 which is referenced as a requirement in the Building Regulations and Standards for England and Wales (Part J), Scotland (Part F) and the Republic of Ireland (Part J).

- This product must be installed by an OFTEC registered engineer

Downloads

Data Sheet: KBB/C - 1/4" Thread

Data Sheet: KBB/D and F - 3/8" and 1/2" Thread

For further information about the KBB, please contact us today.